|

| April 03, 2012 | Volume 08 Issue 13 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New process converts plastic bags into carbon fiber

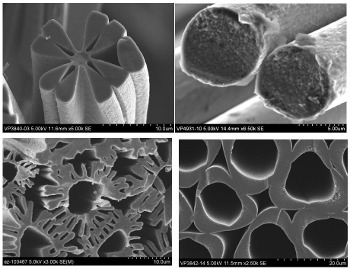

Carbon fibers having unique surface geometries, from circular to hollow gear-shaped, are produced from polyethylene using a versatile fabrication method. The resulting carbon fiber exhibits properties that are dependent on processing conditions, rendering them highly amenable to myriad applications.

Common material such as polyethylene used in plastic bags could be turned into something far more valuable through a process being developed at the Department of Energy's Oak Ridge National Laboratory.

In a paper published recently in Advanced Materials, a team led by Amit Naskar of the Materials Science and Technology Division outlined a method that allows not only for production of carbon fiber but also the ability to tailor the final product to specific applications.

"Our results represent what we believe will one day provide industry with a flexible technique for producing technologically innovative fibers in myriad configurations such as fiber bundle or non-woven mat assemblies," Naskar said.

Using a combination of multi-component fiber spinning and their sulfonation technique, Naskar and colleagues demonstrated that they can make polyethylene-base fibers with a customized surface contour and manipulate filament diameter down to the submicron scale. The patent-pending process also allows them to tune the porosity, making the material potentially useful for filtration, catalysis, and electrochemical energy harvesting.

Naskar noted that the sulfonation process allows for great flexibility because the carbon fibers exhibit properties that are dictated by processing conditions. For this project, the researchers produced carbon fibers with unique cross-sectional geometry, from hollow circular to gear-shaped, by using a multi-component melt extrusion-based fiber spinning method.

The possibilities are virtually endless, according to Naskar, who described the process.

"We dip the fiber bundle into an acid containing a chemical bath where it reacts and forms a black fiber that no longer will melt," Naskar said. "It is this sulfonation reaction that transforms the plastic fiber into an infusible form.

"At this stage, the plastic molecules bond, and with further heating cannot melt or flow. At very high temperatures, this fiber retains mostly carbon and all other elements volatize off in different gas or compound forms."

The researchers also noted that their discovery represents a success for the U.S. Department of Energy (DOE), which seeks advances in lightweight materials that can, among other things, help the U.S. auto industry design cars able to achieve more miles per gallon with no compromise in safety or comfort. And the raw material, which could come from grocery store plastic bags, carpet backing scraps, and salvage, is abundant and inexpensive.

Other authors of the paper, titled "Patterned functional carbon fibers from polyethylene," are Marcus Hunt, Tomonori Saito and Rebecca Brown of ORNL and Amar Kumbhar of the University of North Carolina's Chapel Hill Analytical and Nanofabrication Laboratory. The paper is published online here (fee to access full content).

Funding was provided by DOE's Office of Energy Efficiency and Renewable Energy. UT-Battelle manages ORNL for DOE's Office of Science, the single largest supporter of basic research in the physical sciences in the United States.

Source: ORNL

Published April 2012

Rate this article

View our terms of use and privacy policy